BUSCH PUMPS IN MAPLE SYRUP PRODUCTION: CONSISTENCY AND RELIABILITY

Like LAPIERRE EQUIPMENT, family values are at the heart of Busch Vacuum Pumps and Systems.

The German company is one of the world’s leading manufacturers of vacuum pumps. It has customers in more than 40 countries.

It has always been easy to work with the multinational whose Canadian headquarters are located in Boisbriand. These people have earned our trust for the reliability of their products and the consistency of their service, assets that we ourselves adhere to with each of our customers.

Innovation in maple syrup production: Busch Vacuum Innovation Award

Innovative by nature, we were the first to integrate and develop the potential of vacuum pump technology in maple syrup production, so much so that in late 2018, Ayhan, Sami and Kaya Busch hosted our founder, Donald Lapierre, and his family at the headquarters in Maulburg, Germany.

The Busch family then presented them with an award that it only gives once a year to one of its international customers: the Busch Vacuum Innovation Award. This award is given to a company that has applied vacuum technology in its field of activity with innovative means.

R5 and Mink pumps: a performance factor for maple syrup producers

Several factors explain the increased performance of the maple syrup industry. Among them, our experts and producers agree that BUSCH pumps are a key factor. German products are clearly recognized for their superior performance and design.

Thus, the R5 and MINK pumps are no exception to the rule, first coming to the market for their interesting performance properties and operational reliability. R5, a rotary valve pump with oil recovery reaching 29.9 in/Hg, is also sought after for its robust construction. MINK, a dry-hook pump with a simplified construction, is attractive for its efficiency and low maintenance requirements.

This web space showcases BUSCH products. LAPIERRE EQUIPMENT is the exclusive distributor of the German manufacturer in the Canadian maple syrup industry.

THE VACUUM PUMP EVERY SUGARMAKER TALKS ABOUT, BUILT FOR HIGH VACUUM!

MINK: DRY CLAW VACUUM PUMPS AND COMPRESSORS

| TECHNICAL DATA | MV0040C | MM1102BV | MM1142BV | MM1144BV | MM1252AV | MM1322AV |

|---|---|---|---|---|---|---|

| Nominal motor rating (kW) | 1,3 | 3,0 | 4,0 | 2,2 | 5,5 | 6,5 |

| Nominal motor speed (min) | 4200 | 3600 | 3600 | 1800 | 3600 | 3600 |

| Noise level (dB(A)) | 71 | 79 | 79 | 70 | 79 | 82 |

| Approximative weight (Kg) | 80 | 174 | 187 | 180 | 245 | 270 |

HOW DRY CLAW VACUUM PUMPS WORK ?

HOW MINK MV VACUUM PUMP WORK?

Includes with MINK Vacuum pump: exhaust flap, lubrication valve and intake filter. The installation of the power supply must be done by a properly qualified contractor. The work must be carried out in accordance with the local regulations in effect. The connection kit for progressive start includes everything needed to connect the vacuum pump to the controller. Cable 8 ft. (2.44 m).

BUSCH R5: OIL-LUBRICATED ROTARY VANE VACUUM PUMPS

Since 1963, Busch Vacuum Technics has been manufacturing the most efficient and robust vacuum pumps in the industry. Being the first to manufacture and optimize oil-lubricated rotary vane pumps as we know them today, Busch R5 vane pumps are still today considered the industry benchmark because of their robustness and high operational reliability.

More than 3 million of R5 vacuum pumps are now used worldwide for a variety of demanding industrial applications. Their high efficiency at low vacuum, their energy efficiency and the efficiency of the the exhaust box filtration system invented by doctor and engineer Karl Busch make this pump a powerful and reliable equipment for maple producers who want to operate at low vacuum. Initially developed for the food industry, the Busch R 5pumps has a high tolerance to water vapor, an optimal low energy consumption and air flow over the entire vacuum range

| TECHNICAL DATA | R0021 | R0025 | R0040 | R0063 | R0100 | R0165 | R0205 | R0255 | R0305 |

|---|---|---|---|---|---|---|---|---|---|

| Nominal motor rating (kW) | 0,9 | 1,2 | 1,7 | 2,4 | 3,4 | 6,6 | 6,6 | 9,2 | 10,0 |

| Nominal motor speed (min) | 3600 | 1800 | 1800 | 1800 | 1800 | 1750 | 1750 | 1750 | 1750 |

| Noise level (dB(A)) | 72 | 66 | 66 | 68 | 68 | 79 | 80 | 81 | 81 |

| Approximate weight (kg) | 20 | 36 | 42 | 73 | 73 | 188 | 197 | 208 | 260 |

HOW ROTARY VAN VACUUM PUMPS WORK?

Includes with BUSCH R5 Vacuum pump: exhaust flap and intake filter. The installation of the power supply must be done by a properly qualified contractor. The work must be carried out in accordance with the local regulations in effect. The connection kit for progressive start includes everything needed to connect the vacuum pump to the controller. Cable 8 ft. (2.44 m).

AVAILABLE OPTION

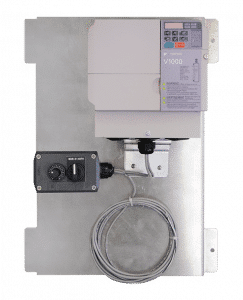

PROGRESSIVE START VARIABLE SPEED DRIVE

•Can be hooked-up to any existing auto start and stop system

•No need for external magnetic starter

•Manual RPM adjustment

•Progressive start to eliminate high power peaks

•Convert single phase power to 3 phase