GLASS BEADS FILTRATION SYSTEM

The Lapierre glass bead filtration system offers a ultimate filtration experience to ensure the cleanliness of your maple sap. By using the recommended filtration media, our system can filter down to 3 microns, which is a superior filtration compared to standard concentrator filtration cartridges (5 microns). This means you can save greatly on disposable cartridges without compromising the quality of your sap.

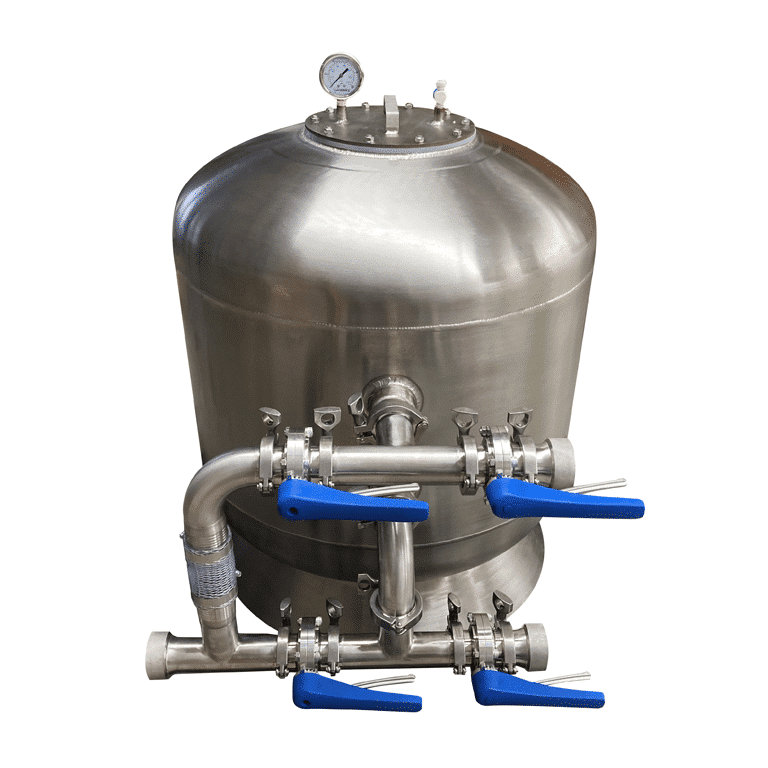

The Lapierre filtration system is easy to maintain with its backwash cleaning process. Furthermore, with its minimal maintenance, you can be sure that your system will function optimally for many years. Our system stands out with its food-grade stainless steel feed, control valves and tank. Additionally, the drain is equipped with a strainer for effective drainage without losing the beads.

It is important to note that this system does not replace cartridges on the RO, which are the final protection for the membranes in case of filtration issues at the bead filter level

INCLUDED:

– Stainless steel filter

– 1 input and 2 outputs

– 4 valves

– Pressure gauge

– Air release valve

– Drainage valve with strainer

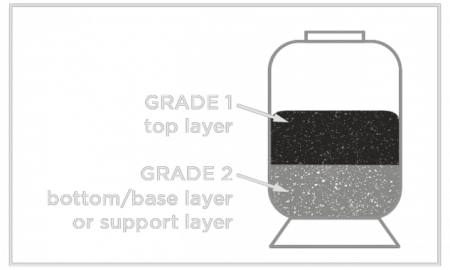

LAYER FILTER MEDIA CAPACITY :

Model 500SS : 32.5 Kg GRADE 2 for the support layer (dimension 0.7 to 2.0 mm) + 32.5 Kg GRADE 1 for the top layer (dimension 0.4 to 0.8 mm)

Model 700SS : 85 Kg GRADE 2 for the support layer (dimension 0.7 to 2.0 mm) + 85 Kg GRADE 1 for the top layer (dimension 0.4 to 0.8 mm)

FILTERING MEDIA CAPACITY (FILTRAL OR PREMIXED)

65 KG (500SS)/170 KG (700SS)

*The premixed filter media will form its layers during the first Backwash cycle.

INSTALLATION AND START-UP STEPS

1. Place the recommended capacity of media in the filter, taking care to tighten the nuts on the cover with its gasket.

2. Connect all necessary piping, making sure it is tight.

3. Perform a 5 to 10 minutes «Rinse».

4. You are now ready for the filtration operation. The recommended pressure is 10 to 30 PSI. Note that a lower pressure is more efficient.

5. Important: do not backwash during the start-up phase. Wait 48 hours before proceeding with the first backwash (10-20 minutes). And then, perform a 5-10 minutes rinse before returning to filtration mode.

OPERATION

1. If the pressure increases by 5 PSI from your set pressure in filtration mode, this indicates that you need to «De-sugar» for 2 to 5 minutes or until the sugar level measurement is acceptable to recover the maple sap.

2. Then, perform a 10 to 20 minutes «Backwash». Follow the recommended flow rate, making sure that not too many glass beads are escaping into the drain. If this is the case, decrease the flow rate using the inlet valve and a flow meter can be used.

3. You are now ready to operate again.

STORAGE

In storage mode, open all valves including the drain valve at the bottom of the filter and the air vent on top, making sure the entire system is drained.

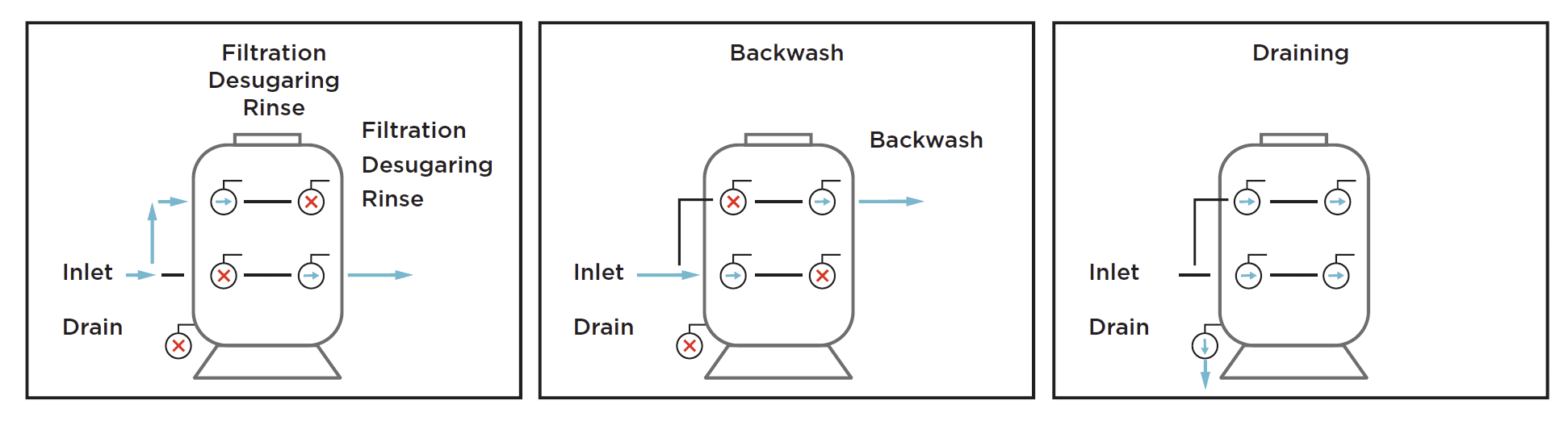

POSITIONING OF THE VALVES ACCORDING TO THE MODES OF OPERATION

Recommended flow rate:

Filtering mode: 30 USGPM (model 500SS) and 60 USGPM (model 700 ss)

Backwash mode: 30 to 40 USGPM (model 500SS) and 60 to 75 USGPM (model 700 ss)

WARNING

– The maximum system pressure is 40 psi.

– Always store in a frost-free environment or drain the filter.

– Do not use corrosive products.

– To avoid placing unnecessary stress on the piping and valves, always stop the pump before restarting a new mode of operation.

– Make sure that at least one of the two outlet valves is open before starting the pump to avoid over pressurizing the system.

– Be sure to clean the filter before filtering the maple sap.

– The filter should be cleaned and sanitized periodically with a product intended for this purpose.