NEW

INNOVATIVE ENERGY PERFORMANCE

At LAPIERRE, innovation has often made the difference. This time is no exception. It is now possible to easily increase your boiling capacity by 15% and reduce your energy consumption by 10%*. That’s what we really call killing two birds with one stone.

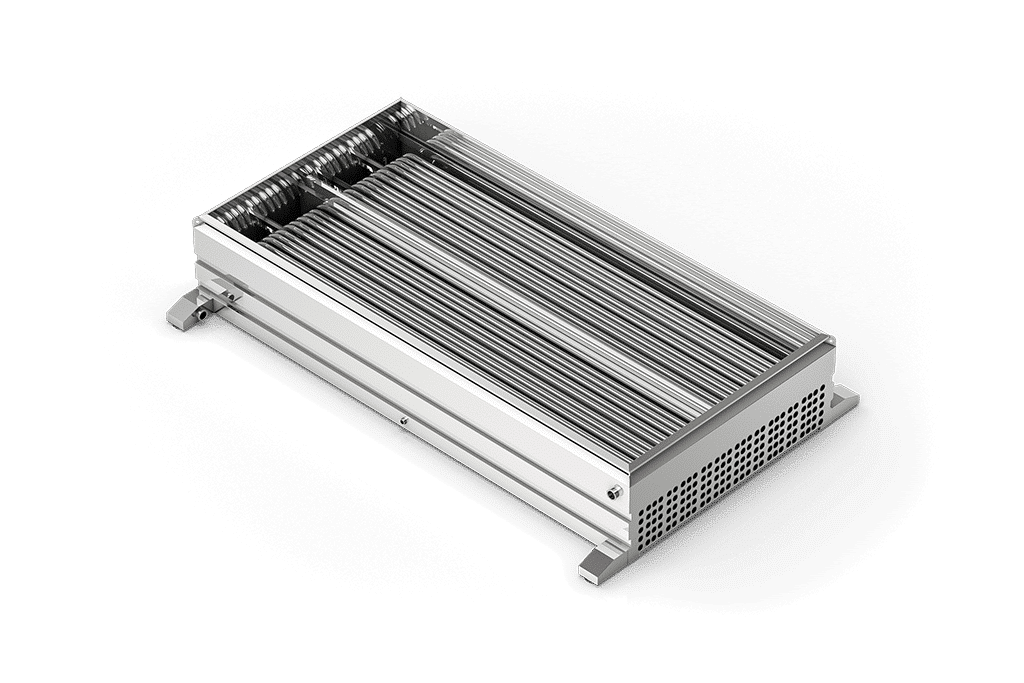

Innovative by nature, LAPIERRE EQUIPMENT offers its brand new high-performance TURBO+ pan. Would you believe that the simple use of round tubes, instead of square ones, can make such a difference in efficiency? Yes, because it simply increases the heat transfer surface in a pan of the same dimensions.

So, if you have a Turbo 3 or Hurricane F5 Turbo evaporator, it is possible to upgrade directly from a Turbo boiling pan to a high performance TURBO+ pan without modifying your evaporator. These pans are available in all sizes for these evaporators

* Results obtained from a test performed on a Turbo 3 evaporator, dimensions 6 x 16 ft., having a 50/50 pan configuration.

WHY DOES THIS INNOVATION MAKE A DIFFERENCE IN YOUR LIFE AS A MAPLE SYRUP PRODUCER?

Because your evaporator is 10% more efficient; because it uses 10% less energy to produce the same gallon of syrup; because you make 10% more syrup with the same amount of energy; because you make 10% more syrup in an hour or in a day; in fact, no matter how you look at it… you are making 10% more.

PATENT PENDING

| BOILING CAPACITY | 15% increase |

| ENERGY CONSUMPTION | 10% reduction |

| COMPATIBLE MODELS (without any modification) | Turbo 3 and Hurricane F5 Turbo |

| AUTOMATED PAN WASHER | Compatible |

TESTIMONIAL

Stéphane Verville, HURRICANE F5 Turbo, 6 x 16 ft., 50/50 configuration

Here are the first impressions of Stéphane Verville, owner of Passion agricole in Saint-Christophe-d’Arthabaska, Quebec: “Compared to the standard tubes pan, the TURBO+ gives us a very different boiling pattern. The distribution is much more even and the boiling is less aggressive, which reduces the use of antifoam.’’

Mr. Verville also brings some interesting findings to the use of round tubes for the TURBO+ rather than square ones: “It is surprising to see how much less solid deposits accumulate on round tubes. The expansion and contraction caused by the cold and heat naturally loosens the Sugar sand that have accumulated on the round tubes, which then fall off and go into the decanter. This reduces the need for acids and also reduces the time needed to clean the system. Finally, the superior heat exchange brings an appreciable increase in evaporation.’’