Three-level tapping

FOR OPTIMAL AND SUSTAINED PERFORMANCE OVER TIME

Those who saw the video capsule put online on Érable & Chalumeaux on March 1, 2019 understand how surprised I was to see that a maple syrup producer had applied a tapping model that I had developed 20 years earlier. The surprise was even greater when we studied maples and found that the model worked! This method would allow them to always cut into healthy wood in perpetuity, and therefore have higher yields from generation to generation.

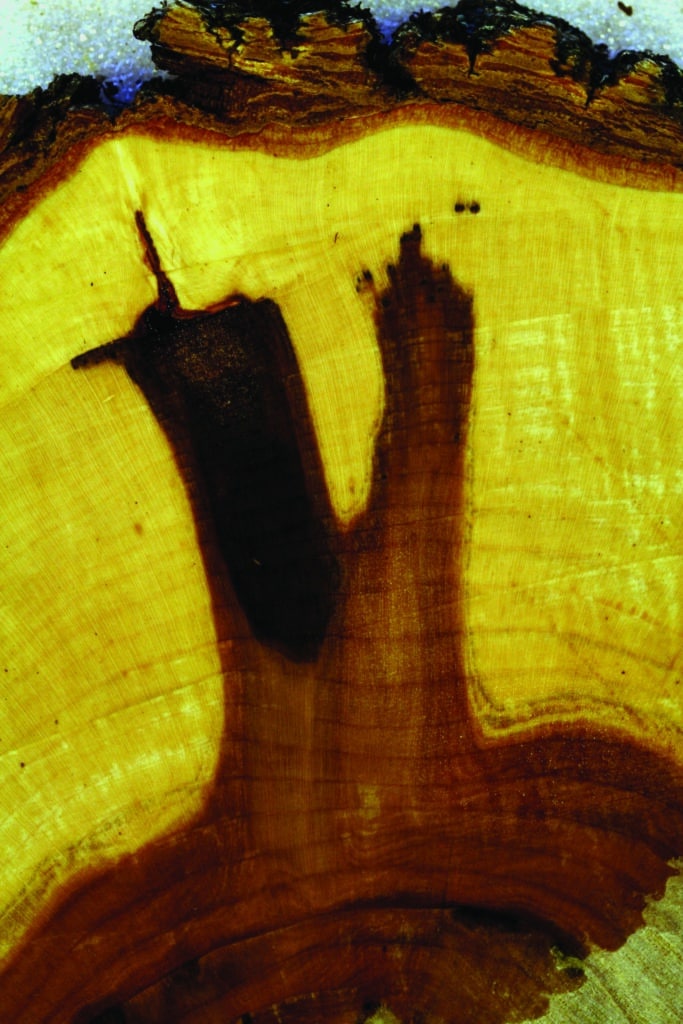

If we go back to the source, I had developed this tapping model following projects in which we studied the inside of the tapping area and found that the accumulation of dead wood in the tapping area was faster than new wood produced by the tree.

Image 1: A cut showing a 20-year-old tapped tree that has almost no living wood left.

One of the reasons for the rapid accumulation of dead wood is that when 2 taps are brought closer together (less than 2 inches wide and less than 16 inches high) the cuts of the 2 taps tend to weld and form an injury that can be 4 times greater.

Image 2: Fusion of 2 taps made at 8-year intervals.

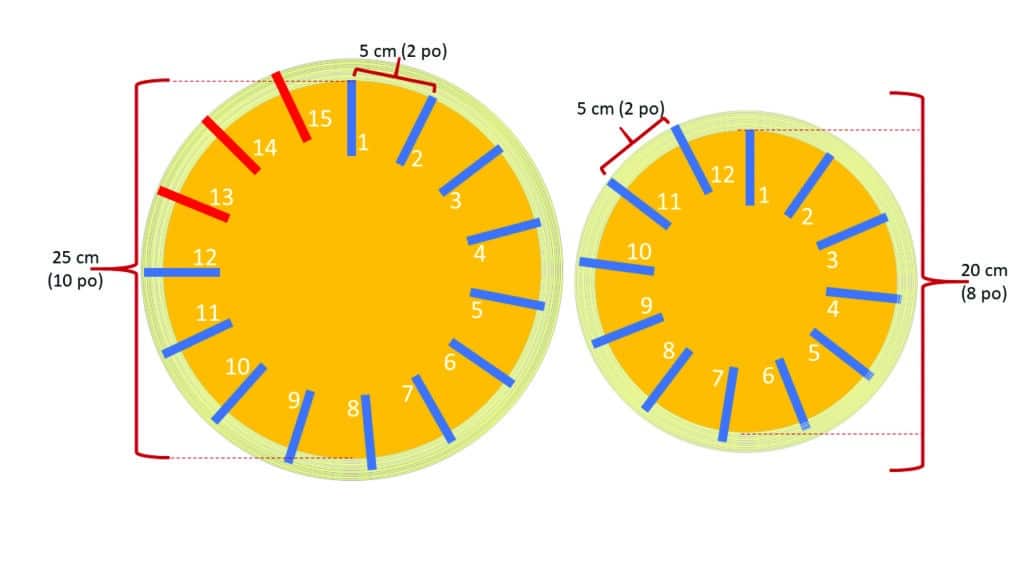

So I reflexively thought that 20 cm (8 inches) in diameter for a maple tree was too small to make a first tap. By modelling the tapping on maples with an average growth of 1.2 mm radial per year in an area of +/- 40 cm (16 inches), I quickly noticed that starting the tapping at 25 cm (10 inches) in diameter instead of 20 cm (8 inches) only gave us 3 more years (15 years) before having to put a new tap within 5 cm (2 inches) of an old tap, compared to 12 years if we start to tap a tree at 20 cm in diameter (Image 3). It was therefore clear to me that starting to tap maples at 25 cm in diameter was not a significant conservation measure.

Image 3: Model showing that starting to tap maple trees at 25 cm in diameter, instead of 20 cm in diameter, does not significantly improve conservation if the taps are placed on a single level.

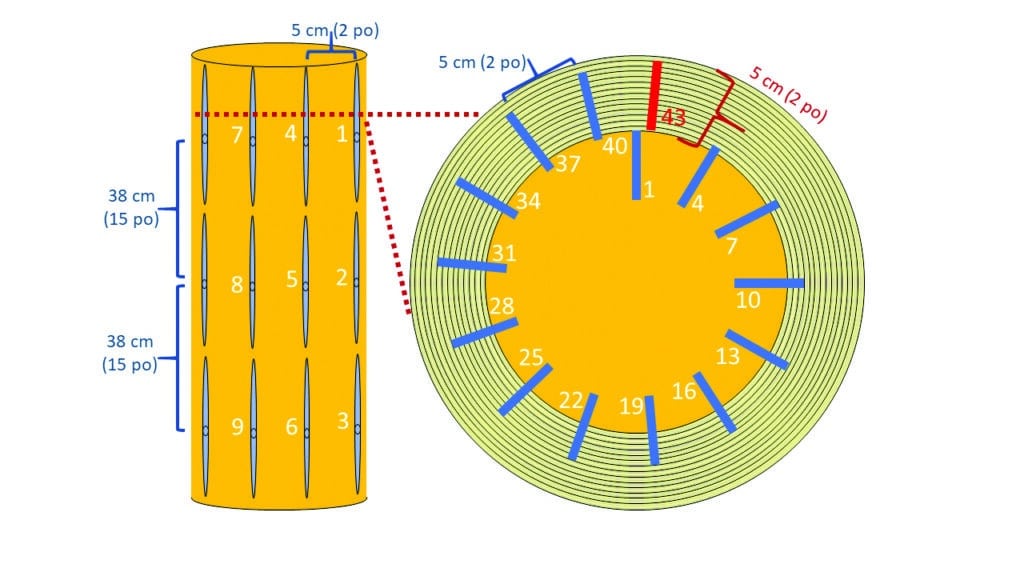

By refining the model (Image 4) I understood that the only way to succeed in the long run to save maple trees with average growth combined with 5 cm (2 inches) deep tap is to systematically cut three rows of height (vertically) spaced 40 cm (16 inches) hole by hole, and to separate the 5 cm (2 inches) wide taps (horizontally). By doing so, the 42 years required to circle the tree will have allowed the maple to grow enough to produce new wood 5 cm thick: this method allows the maple producer to tap against the old first tap in 100% healthy wood. It should be noted that this method allows only one tapping per tree per year.

Image 4

Today, we can assume that the new sap spout diameter standard is 1/4 inch. This sap spout now allows us to vertically distance the taps by 38 cm (15 inches hole to hole).

It is very motivating to see that it is possible to leave a significant maple syrup potential to future generations by using my method!

Thanks to Stéphane Guay, d’Érable & Chalumeaux

https://www.erable-chalumeaux.ca/